In today’s food industry, brands need solutions to ensure their products are safe while making workflow and staff movement easier. Strip curtain roll installations have grown necessary in food processing areas because they keep different hazards out, protect food from contaminants, and are compliant with food safety guidelines.

Temperature Control and Energy Efficiency

It is difficult for food manufacturing to keep temperatures the same in each processing zone. Some facilities must provide cold, hot and standard temperatures for different job areas all in one venue. The use of strip curtain roll systems stops excessive heat travel between nearby areas and allows staff and tools to go through with ease.

Whenever doors in a chilled storage area open, a lot of cold air escapes. Doors that open completely let in a lot of air, which requires the refrigeration system to work harder to keep temperatures right.

Prevention of Contamination and Good Hygiene

Food manufacturers must take special measures to stop possible contamination during food production. Particles in the air, insects and contact between different processing regions regularly harm the quality of products and customer health. The presence of strip curtain systems greatly cuts down on the risks of contamination, even with flexible factory operations.

Many types of food need their processing area to make sure allergens or incompatible foods do not mix. Strip curtain roll installations let buildings create zones that can be moved as production demands change, without having to build permanent walls.

Workflow Efficiency and Personnel Safety

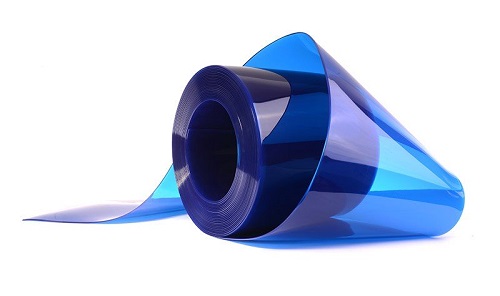

Food processing operations require constant movement of personnel, equipment, and products between different areas of the facility. Traditional doors can create bottlenecks and safety hazards when workers carry heavy loads or operate machinery. Strip curtain roll systems allow hands-free passage that improves workflow efficiency while reducing workplace accident risks.

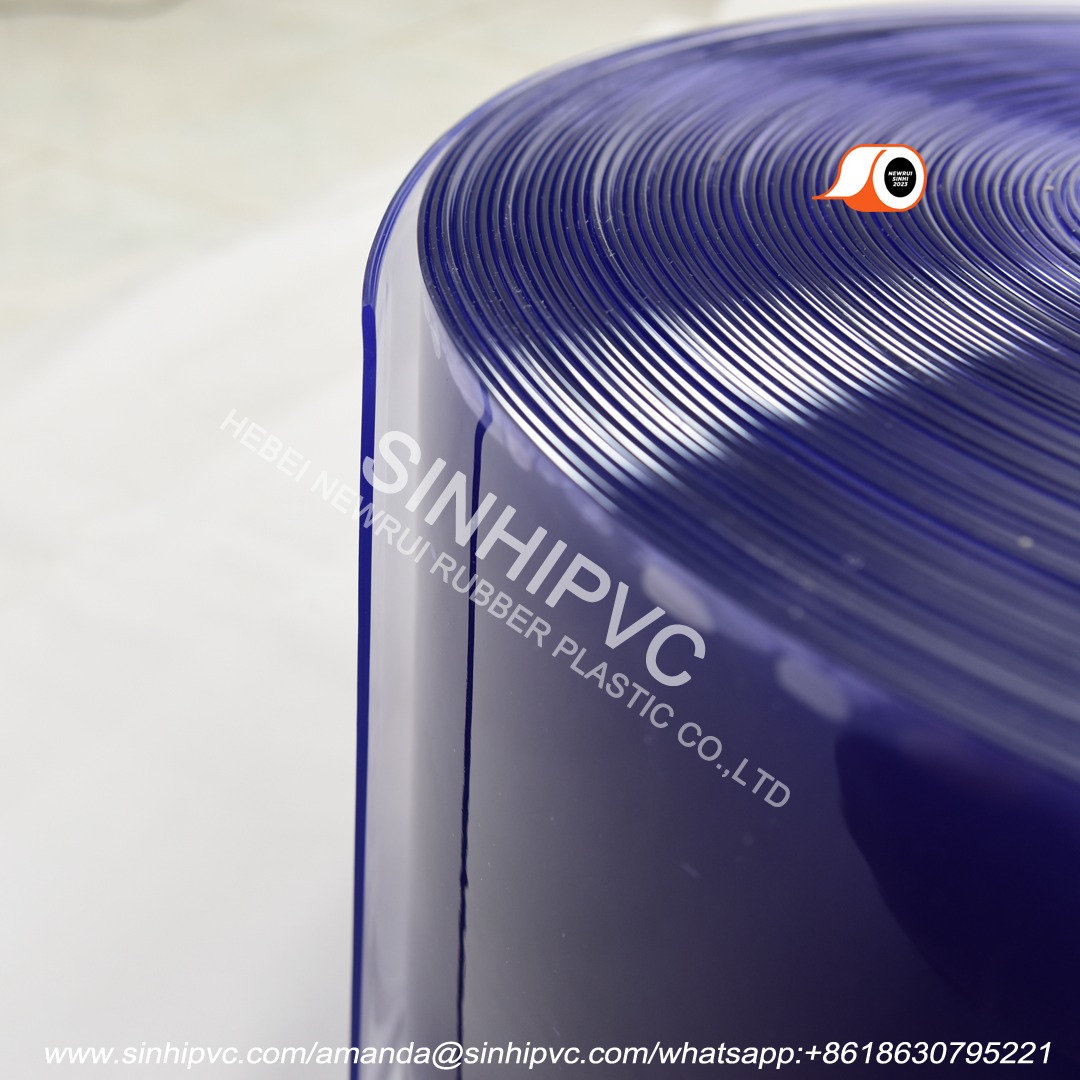

Forklift operations become safer and more efficient with strip curtain installations that eliminate the need to stop and manually operate doors. Drivers maintain clear visibility through transparent curtain materials while equipment passes through easily without requiring additional personnel to assist with door operations. Reduced handling requirements minimize product damage risks and improve overall operational efficiency.

Noise Reduction and Work Environment Quality

Food processing equipment often generates significant noise levels that can create uncomfortable or unsafe working conditions for personnel. Strip curtain roll installations provide sound-dampening properties that reduce noise transmission between different processing areas, creating more comfortable work environments and improving communication between workers.

Quality control activities require environments with minimal external distractions where personnel can focus on detailed inspection tasks. Strip curtains help create quieter zones for quality assurance work while maintaining access to production areas when needed. Improved working conditions contribute to better employee satisfaction and reduced turnover rates.

Compliance with Food Safety Standards

International food safety standards require documented measures to prevent contamination and maintain hygienic processing conditions. Strip curtain roll systems help facilities demonstrate compliance with HACCP principles and other regulatory requirements by providing verifiable contamination control measures.

Regular inspection and maintenance of strip curtain systems ensure continued effectiveness in protecting food products throughout processing operations. Transparent materials allow visual inspection of curtain condition while easy replacement procedures minimize downtime when maintenance becomes necessary.